I am finally back in the T-shirt Quilt saddle. I am determined to get this baby off my design wall and move on. That whole sincere, earnest discussion about small projects?

I say: BRING IT ON!

That means that the T-shirt quilt has be OFF the design wall. I am not folding it up and putting back in the UFO area. It has to be ready to go to the quilter. And THAT means that I have to work on it.

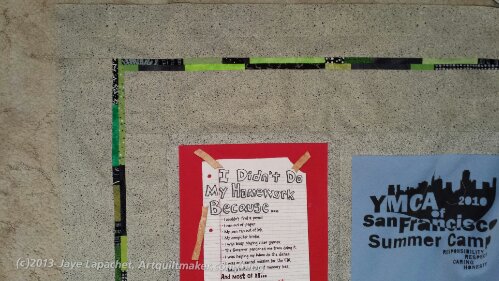

So, I am working on the border. The green border is made up of 1″ wide strips, alternating green and black, of varying lengths. which is very thin.

Thin=tricky. Tricky because when chain piecing or sewing using the leaders/enders technique, there isn’t enough thread between the pieces to help keep them from unravelling. At 1″ wide, there are only a few stitches to hold the black and green pieces together. Not chain piecing feels awkward and wasteful. Thus, the strips are very fragile. I pulled several apart as I was sewing them to the larger quilt. Of course, I fixed them, but what a pain. I could have solved the problem by back stitching at the beginning and the end of each border piece, but that would have been tedious, too.

Why put up the with drama, you ask?

Once completed, the border is very effective. The border is intended to “float” in larger borders on either side. You can see the floating effect in the photo above. In this case, the two thin green & black borders will “float” in the grey. Such a border adds interest to the quilt as well

It is, however, really a pain to make. Did I mention that the strips are 1″ wide?

I am pretty sure you will sincerely dislike me when I say this, but I am going to say it anyway. Thin borders need tightly woven fabric.

Yes, thin borders need tightly woven fabric.

Why?

Some fabrics tend to unravel and some of the fabrics I am using seem to be unraveling more than others. The Modas are particularly bad in this area. You may love the Moda designs, pre-cuts and designers, but their fabrics are somewhat loosely woven, which means that they tend to ravel.

If you have a 6″ square and one thread frays off the edge, who cares? It won’t matter, because you can easily account for it. With a 1″ strip one thread fraying can make a difference in how straight the border is. I could have used Fray Check, but didn’t think of it.

Tightly woven fabric tends to fray less and, thus, be easier to use when working with thin pieces. Kona cottons seem to be tightly woven as do a lot of hand dyed fabrics. It is pretty easy to tell tightly woven fabric, because it isn’t as easy to see through.

I have only a bit to go to finish the top, then on to the label and the giant border. Wish me luck.